Singapore

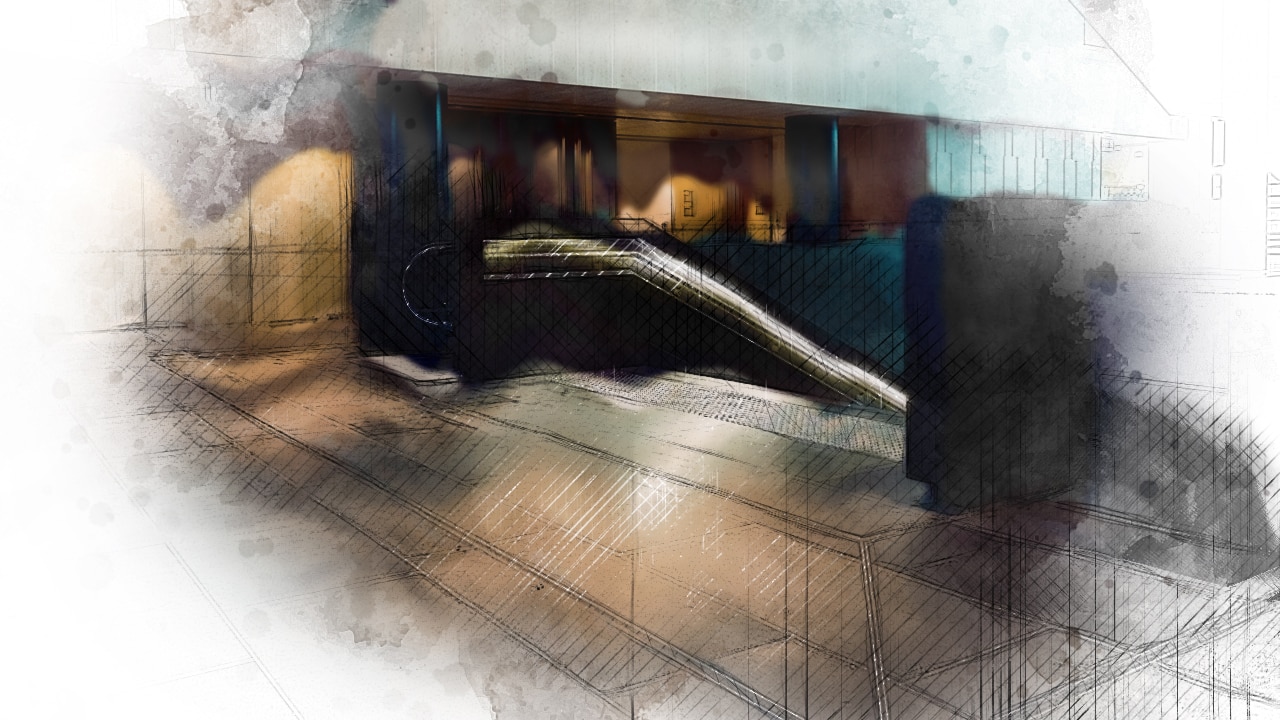

501 Series-Pan System Expansion Joint Covers

Formidably built to cover the endless tussle between buildings and Mother Nature, INNIVATE’s expertly-engineered expansion joint cover systems mean that architects don’t have to worry about compromised aesthetics.

With a strong, shared belief in innovative collaboration, INNIVATE partners inpro to deliver a quality range of market-leading expansion joint cover systems.

Formidably built to cover the endless tussle between buildings and Mother Nature, INNIVATE’s expertly-engineered expansion joint cover systems mean that architects don’t have to worry about compromised aesthetics.

With a strong, shared belief in innovative collaboration, INNIVATE partners inpro to deliver a quality range of market-leading expansion joint cover systems.

Expansion joints are predetermined gaps in building structures designed to allow for environmental movement caused by temperature changes, wind, or earthquakes.

Movement can be caused by (1) temperature – this affects every single built structure; (2) wind sway – also known as shear, this affects high-rise buildings especially; (3) seismic activity – regionally based movement in 3 directions, these are often caused by earthquakes or tremors

1. What is the joint width?

2. What are the movement parameters?

3. What are the floor loading requirements?

4. What type of project is this?

5. What aesthetic value are you trying to achieve?

6. Hygienic requirements (eg. Does the joint cover need to be sealed?)

7. Additional considerations: Does the building require Fire Barriers and/or Moisture Barriers? What about acoustic considerations?

8. What is the budget?

Note that expansion joint systems need to accommodate the minimum and maximum movement requirements. To avoid confusion, it is best to define movement through dimensions (eg. A 6” expansion gap that moves 3” in or 3” out = 3”-9” operating range. The term percentage (%) of movement is sometimes used, but it is defined differently by each manufacturer and thus potentially confusing.

Expansion joint systems incorporate everything from acoustics and waterproofing to fire and environmental heat. They are the unsung heroes maintaining building integrity in the face of earthquakes, hurricanes, fires, and the everyday march of Mother Nature. From ensuring smooth transitions for rolling equipment like carts, gurneys and wheelchairs, to preventing the spread of smoke and fire, each expansion joint cover system has building protection integrated into its design.

INNIVATE’s range of expansion joint cover systems include compression seals, floor expansion joint covers, wall and ceiling expansion joint covers, exterior expansion joints, foam seals and fire and moisture barriers, seismic joint systems,and facility protection.

View the full range at www.inprocorp.com/products/expansion-joint-systems

PAST PROJECTS WITH INNIVATE